Our products

-

XPS Thermo-bonding machines

With automatic feeding for the production of XPS multi-layer panels

-

Extrusion Dies for XPS panels

Extruding panels with finished thicknesses from 30 mm to 120 mm and with a net width of 600 mm.

Our projects

-

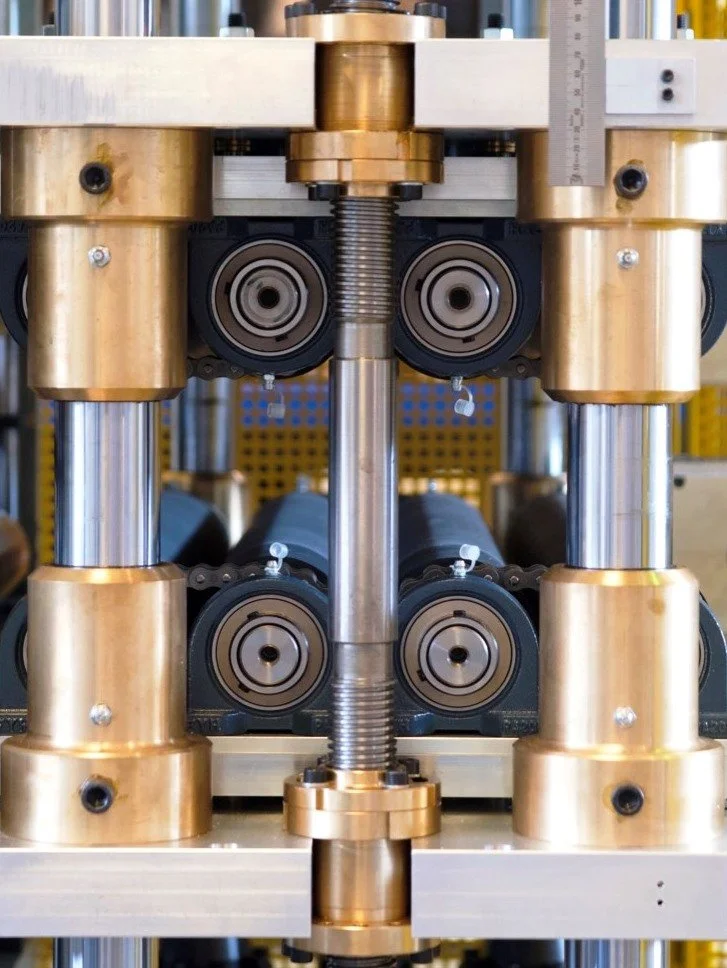

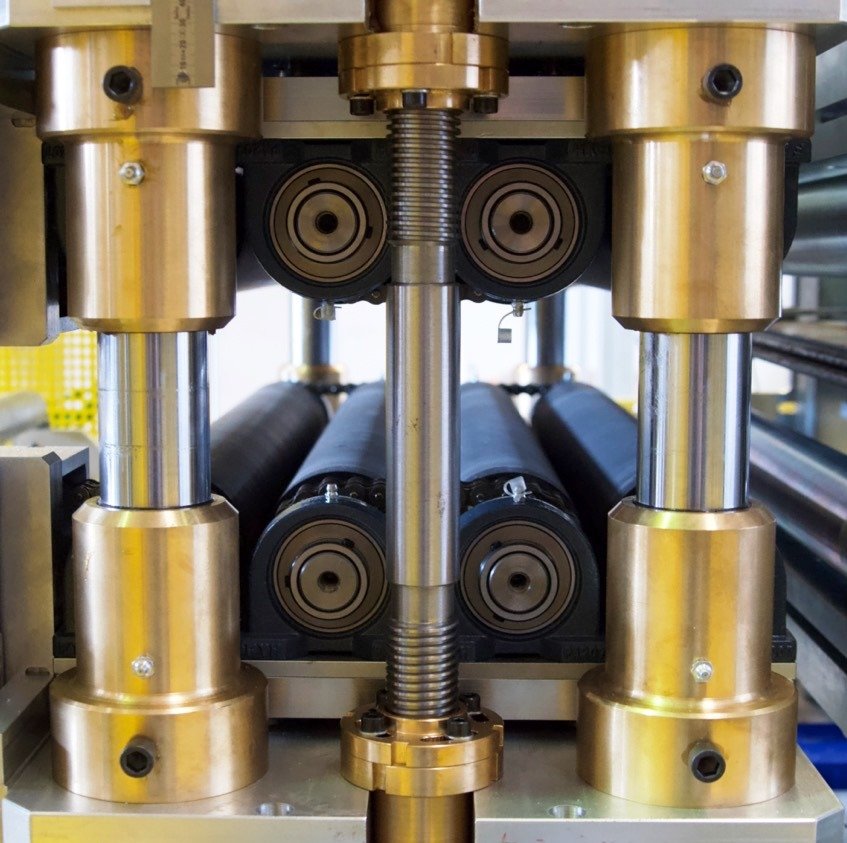

XPS THERMO-BONDING MACHINE

As a result of its long experience in the sector of XPS panels, the flagship of CAMM are the machines for producing high thickness XPS panels by thermo-bonding panels with lower thickness. These machines allow hot welding of XPS panels by an automatic laminating process, which guarantees a high processing speed, avoiding, at the same time, the use of adhesives and/or chemical components. They also permit to weld without prior removal of the first panels’ layer.

The use of the thermo-bonding machine within the extrusion lines helps to reduce the thickness changes and allows the possibility to work always in conditions of maximum efficiency and higher process stability, thus enabling to drastically reduce the production costs.

CAMM developed this sealing system in 2009-2010 and, since then, our thermo-bonding machines have been supplied to important customers in Italy and in Europe.

High operational versatility, thanks to the possibility of thermo-bonding either 2 or 3 panels, working both "in-line" and "off-line", depending on the production needs.

-

EXTRUSION DIES FOR XPS PANELS

Another relevant CAMM product is the extrusion die for the manufacturing of XPS panels.

This equipment allows extruding panels with various finished thicknesses and various width.

This extrusion die is equipped with a customizable extruder attachment system.

Company profile

CAMM is a company that has been operating in the field of mechanics and process automation for over 30 years and is able to meet the multiple needs of its customers, ensuring the quality of the product and service as well as attention to detail.

The long operational experience has allowed CAMM to achieve top-level results in the field of processing extruded expanded polystyrene foam panels (XPS). Over the years, important multinational companies in this sector have chosen to entrust CAMM with the construction of particularly complex and innovative systems.

FROM DESIGN TO CONSTRUCTION

Both the design and the assembly of all C.A.M.M. machines are entirely performed within its own factory. The most modern technological supports and tools are used throughout all the processes.